Working with an expert manufacturing partner can help to utilize the best properties of both similar and dissimilar metals

In aerospace, metal diffusion bonding is an essential joining method for achieving a high-purity interface when two similar metals require superior structural integrity. The process involves applying high temperature, and pressure to metals mated together in a hot press causes the atoms on solid metallic surfaces to intersperse and bond.

There are probably no other commercially viable materials joining process that can produce such consistent results today. The applied pressure induced by a hot-press tool, combined with software and loop-back sensors for precise control to within micrometer accuracy, can produce constant pressure over several square feet of area for a component assembly. As a result, this technology has attracted the interest of design engineers in the semiconductor, aerospace, and energy industries.

With such a high degree of process control, the diffusion bonding process is increasingly used to join dissimilar metals in aerospace. Commercial processes of interest are titanium to iron-nickel alloys, titanium alloys to stainless steel, and even some aluminum to metal applications. The process also enables coupling between different alloys in the same material group, such as mild steel, tool steel, and Metal-Matrix Composites.

To successfully use diffusion bonding in aerospace, an understanding of the complexities of the interface and its effect on the chemical and thermo-mechanical properties of the bond is required. However, with the industry’s traditional focus on welding and brazing, there has been minimal formal education on diffusion bonding, according to Thomas Palamides, Senior Product & Sales Manager – Industrial Furnaces, PVA TePla AG, a global manufacturer of industrial furnaces and PulsPlasma nitriding systems.

“Combining the beneficial properties of different metals is the main reason to explore diffusion bonding. However, when aerospace manufacturers reach out [to us about it], they often understand little about how the parts should be designed, prepared, or handled. They may have questions about process data and need guidance on issues such as heating, cooling, and pressing rates,” says Palamides.

Consulting with an expert aerospace manufacturing partner is often the quickest way to consider the possible benefits of diffusion bonding. The approach can also help to tailor diffusion bonding to the manufacturer’s process cost-effectively.

The Benefits of Diffusion Bonding

The importance of designing a dissimilar metal joint often lies in a desire to expose the correct metal surface to specific environmental conditions where a single alloy may not perform as well. Another reason is to introduce material systems that are lighter in weight or provide a level of corrosion resistance that can only be achieved by “packaging” dissimilar metals.

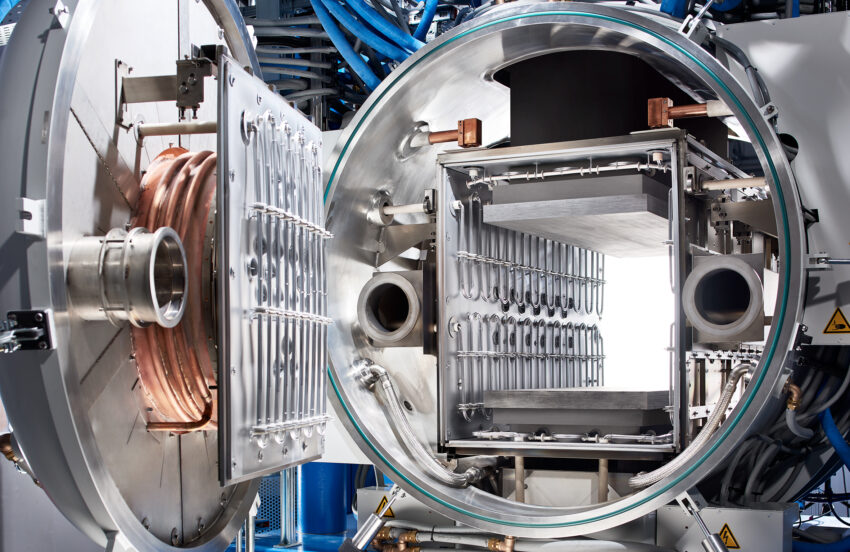

Diffusion bonding also has tremendous potential applications for conformal cooling. The concept is to bond layers of sheet metal that contain machined channel/microchannel structures. When combined, the channels can provide for cooling or heat dissipation. The layers can be bonded up to a stack height of 600mm in the MOV diffusion bonding press, retaining the strength as the parent materials.

Another application related to conformal cooling is for plastic injection molds made in 2-layer designs of low alloyed tool steel with stainless steel such as STAVAX.

Understanding Diffusion Bonding

Academia has researched dissimilar joining for decades, and much of the focus has been on high-performance materials like titanium alloys. According to Palamides, expanding beyond commercially pure (CP) titanium, one often finds the existence of an intermetallic layer at the mating interface after processing. “The influence of the solute elements, such Cu, Ni, and Ag are the major drivers for the intermetallic layer formation in titanium,” he says.

The diffusion bonding process can occur as either a solid-state or a liquid-phase bonding process. Similar pure material bonding has historically been as a solid-state operation. This method simplifies the process from an assembly standpoint, as faying surfaces can be easily matched before placing a charge into the furnace. Alignment pins and tack welding may be used for this process as well. Because no liquid phase is present in diffusion bonding, slight deformation occurs at the surface. This results from applied pressure used to flatten surface asperities and break up residual surface oxides before bonding.

In the liquid-phase diffusion bonding process, an interlayer typically melts at the faying surfaces. In this instance, lower pressure than solid-state diffusion bonding is used, and even less deformation occurs at the surface. Depending on the thermal cycle and composition of the interlayer materials combination and the interlayer selected, an interdiffusion occurs between the interlayer and base materials on either side of the joint through the metallurgical processes known as a eutectic or peritectic phase change.

The thickness of the final intermetallic reaction layer is a result of first from the liquid-phase diffusion and second, from the solid-state diffusion. Bond strength is a function of the intermetallic compounds formed, the thickness of the intermetallic zone, and anomalies, such as voids, at the interface.

Exploring Diffusion Bonding

There are several ways for an aerospace manufacturer to investigate how diffusion bonding of dissimilar metals could benefit their process. Much scientific literature is readily available for specific material combinations and processing times and temperatures depending on the application. For example, Kavian O. Cooke and Anas M. Atieh conducted an exhaustive review published in 2020 titled Current Trends in Dissimilar Diffusion Bonding of Titanium Alloys to Stainless Steels, Aluminum, and Magnesium Journal of Manufacturing and Materials Processing.

While ample research exists on the subject, design engineers can still find it challenging to convert the information into real-world manufacturing of a specific part. When this is the case, it can be helpful to partner with experts with an extensive database of successful processing parameters from previous applications and access to industrial-scale equipment.

“In most cases, we start talking with the aerospace manufacturer about introducing new designs, and consult on possible materials, designs, and also conduct pre-bonding runs as needed,” says Palamides. PVA TePla provides support, including specific material combinations, processing times, and temperatures.

He notes that proper design will allow diffusion bonding of assemblies, whether an intimate interface or multiple interfaces that are planar parallel simultaneously. However, surfaces that are not perpendicular to the compressive force of the hydraulic ram will not bond properly.

Palamides says that the manufacturer begins by working with their mechanical, thermal, and modeling teams. Once a design is complete, the next step is to fabricate trial samples that are truthful to the characteristics of the final interface.

“Locate a vendor who can perform contract service trial runs. Propose a test matrix to ensure your schedule is aligned with project goals,” says Palamides.

Advances in Diffusion Bonding Equipment

Despite its benefits, the use of diffusion bonding in aerospace has been limited by more practical considerations until recently. Specifically, the size limitation of the furnace chamber and limits to the amount and uniformity of the pressure applied across the entire surface area of the part. Run times are also long, often lasting an entire day.

Advances in high vacuum hot presses now allow superior pressure control and rapid cooling systems to improve the bond, increase yields and significantly decrease cycle time.

In the case of the pressure applied, for example, integrated single cylinder hydraulic presses can apply a consistent, measurable amount of force. However, this provides very little control over large parts with more complex geometries. To improve force distribution, thick graphite pressing plates (10”-15” in height) mate the metal layers together at a more consistent pressure. Unfortunately, this takes up furnace space while adding to the time to heat the surfaces of the metals.

Today, manufacturers such as PVA TePla offer multi-cylinder systems with large pressing plates that can accommodate various parts. The largest, the company’s MOV 853 HP, can process substrates as large as 900mm (35.43”) x 1250mm (49.21”), which is quite large for diffusion bonding. The pressing force is 4,000 kN.

By controlling each cylinder independently, the integrated press provides remarkably consistent pressure across the entire surface. The MOV also comes with built-in pressure transducers along the bottom of the pressing plate. The individual hydraulic cylinders can be adjusted in the software to achieve uniformity even over large areas based on the sensor feedback.

PVA TePla has optimized a physical ink test method that identifies areas on the substrate where uneven pressure is applied.

“Today’s equipment provides detailed measurements of the material properties during bonding,” says Palamides. “This valuable feedback can show how the materials are compressing, if it is being crushed, and if a transient liquid layer is forming – and other KPIs of the procedure.”

Verifying the Integrity of the Bonding Interface

To ensure the quality of the interface, Palamides recommends analyzing samples through non-destructive inspection techniques, such as Scanning Acoustic Microscopy (SAM). Or more costly analysis performed using Scanning Electron Microscopy/Energy Dispersive X-ray Spectroscopy (SEM-EDS). Subsequently, trial samples may be destructively analyzed and fabricated into standard mechanical test specimens to collect repeatable data.

While there is growing interest in diffusion bonding, all applications require thorough research to optimize the joining process. Only a few global firms can work with aerospace manufacturers through the process with the ability to advise on commercial system adoption. From the beginning, partnering with an expert in diffusion bonding will give manufacturers a competitive edge from part design through production ramp-up.

For more information, contact PVA TePla America at 951-371-2500 or 800-527-5667 or visit www.pvateplaamerica.com.