A small utility in Tennessee installed a complete automated power factor balancing system without complex SCADA

For the power generation industry, maintaining power system balance as closely as possible to the ideal power factor (PF) of 1.000 using correction capacitors and other technology is critical. Power factor is a measure of how effectively electricity is used, with an equal 1.000 PF benefiting both the customer and utility, and a low or high PF indicating poor electrical power utilization. A low power factor can overload generation units making them work harder for the same amount of power. A high power factor can cause instability to equipment on the distribution network as the voltage rises beyond normal capabilities. In contrast, improving the PF can maximize current-carrying capacity, improve voltage to equipment, reduce power losses, and lower electric bills.

“The challenge for small municipal utilities and co-ops required to maintain proper power system balance is that they are more susceptible to large industrial loads and typically do not have complex SCADA systems to automate the process”, says Ryan McAuliffe, Sales Engineer, NovaTech Automation, a substation automation company that has served the power transmission and distribution market for over 30 years. In addition, smaller utilities may not have enough operators to manually monitor and effectively control the PF on a 24/7 basis.

Fortunately, cost-effective, self-contained, automation platforms can utilize programming logic schemes to maintain power system balance, minimizing the need for manual oversight and control.

“Today, automation platforms can maintain system balance with PF at virtually 1.000 with accuracy to 3 decimal places. The control system calculates whether the power system is out of tolerance, and if so, initiates a correction using the capacitor banks to keep the power factor at 1.000,” says McAuliffe.

Automating System Balance

In a recent example, a small municipal power utility in Smithville, Tennessee required an automatic capacitor control logic scheme for their distribution network.

“The municipal utility has a small distribution network and is contracted [with a major Transmission Network Operator], under penalty of fine, to keep the PF of the power system as close to 1.000 as possible. However, the system includes a rather large industrial customer, so the utility needed a better way to manage their PF,” says McAuliffe.

The utility has two substations with interconnecting feeders through their distribution network with the feeder circuit breaker on either end acting as the open or closed point. The capacitors are positioned outside the substation fence at various locations on those interconnected feeders.

As a solution, the utility chose to implement a complete integrated power balancing system including capacitors, a capacitor bank controller, circuit breakers, and a controlling RTU.

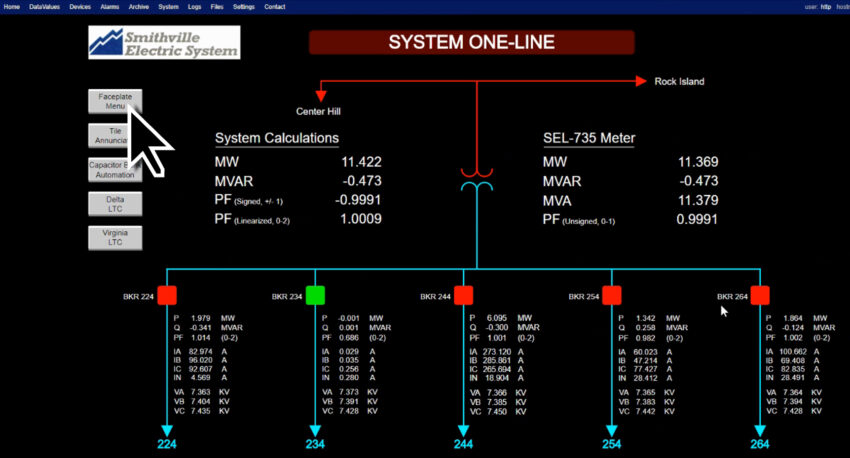

All monitoring, control, visualization, and security of the integrated utility power balancing system is provided by the OrionLX Substation Automation Platform by NovaTech. The OrionLX is a communication and automation processor that can be integrated with practically any equipment, usually microprocessor-based relays, meters, and other IEDs as well. It can connect to SCADA system or itself be a basic SCADA system.

The system uses open-source web technologies and pre-configured template pages. This simplifies the building of interactive SCADA and local HMI screens to view data from connected IEDs and RTUs using standard web browsers. Engineers can open multiple browsers to have graphical interfaces for the different substations and key remote monitoring features on different tabs, which eases network monitoring. Multiple users can be logged in simultaneously.

“With the substation automation platform, the utility did not need a dispatcher for PF balancing, only a supervisor to oversee the facility,” says McAuliffe.

According to McAuliffe, the platform’s System Balance scheme helps to ensure that each substation maintains a 1.000 power factor. The scheme will initialize values and then load all previous retentive values or default values if there are no retentive values. With the scheme, an overall leading power system state will turn off one or more capacitors, and an overall lagging power system state will turn on one or more capacitors, providing alerts and control.

To ensure that individual feeders are in balance and within tolerance, a second logic scheme has been proposed for Individual Feeder Balance that will run every five minutes after completion of the primary scheme. This is needed due to the configuration of the utility’s distribution network assets. Although total substation power factor can be balanced, it is possible to have two feeders out of balance in the condition of one lagging and one leading. The second scheme looks at individual feeder power factor tolerance and makes corrections as needed.

Together, the primary and secondary balancing schemes provide integrated Volt-VAR regulation and optimization. The schemes automatically switch capacitor banks in and out to maintain power factor very close to balance, summing PF on each feeder and comparing it with the metered value reported to the power provider. The automation includes features to reduce wear and maintenance such as never switching the same capacitor bank twice in a row.

The system maintains the ability to manually control all capacitor banks and provides web-based HMI for monitoring and control of breakers and IEDs in substations.

“Automated power system balancing comes in handy for smaller utilities because they don’t need to monitor as closely. With installation comes more automatic control that can be scaled up to the number of required substations,” says McAuliffe.

Overall, the primary and secondary balancing schemes have been extremely beneficial for the small municipal utility in Tennessee. The schemes have reduced the labor required for the utility to look after the distribution grid, and it has maintained almost full power factor compliance with the Transmission Network Operator.

For more information on SCADA solutions from NovaTech Automation, visit HYPERLINK www.novatechautomation.com or call (913) 451-1880.