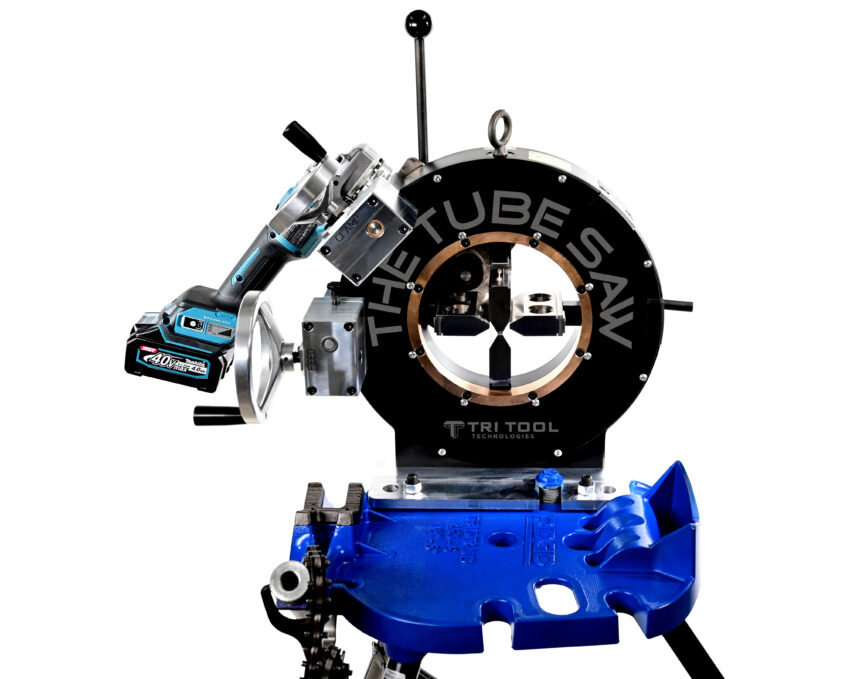

New cordless Tube Saw cuts the widest range of piping and tubing sizes and materials with greater precision, efficiency, and longevity.

The semiconductor, pharmaceutical, and aerospace industries all require extensive piping and tubing systems to deliver essential liquids and gases under high pressure to critical equipment and systems within facilities, equipment, and infrastructure. To install or replace this piping and tubing, the mechanical contractors that serve these industries often utilize tube saws to cut the materials to length prior to welding. This means any cuts in the piping or tubing need to be extremely precise, square, and free of contaminants such as tiny metal fragments.

Unfortunately, typical tube saws often are not engineered to reliably make such precise cuts, “particularly given the variations in pipe and tube sizes, wall thicknesses, and exotic material types from industry to industry,” says Chris Belle, CEO of Tri Tool Technologies. Founded in 1972, Tri Tool Technologies is a leading provider of machining tools, custom machining solutions, and on-site services.

In the past, mechanical contractors frequently had to procure multiple tube saws to cut piping and tubing of different sizes and types. Moreover, this equipment traditionally required replacement in less than a year.

Now, a newly designed tube saw from Tri Tool Technologies is able to cut a wide range of tubes and pipes, ranging from 1/4″ to 6″ OD and 1/8″ to 6″ ID respectively. Its capabilities include precision cutting of thin wall stainless steel within the range of .035″ to .150″ (schedule 10 pipe), as well as the ability to handle challenging materials like titanium and Inconel ®.

The machine increases productivity by enabling quick diameter changes without the need for tools, and it can make cuts in a single pass. The advanced tube saw demonstrates superior performance in cutting thin walls, including specialized metals such as titanium tubing, which is often brittle.

To give mechanical contractors the freedom to use The Tube Saw anywhere, the machine is designed for use with a cordless motor but can be used with a corded motor as well. Ambidextrous interfaces provide the capability to reconfigure the tool for use on either side of the machine, accommodating both left-handed and right-handed users. This can also facilitate placement of The Tube Saw in tight spaces or against a wall.

For more info, contact Tri Tool Technologies at phone: (888) 305-1337 or (916) 571-0003; or web: www.tritool.com.