Like a well-coordinated pit crew, an innovative rupture disk manufacturer now streamlines the high-quality custom prototype process to accelerate the service to OEMs. This expedites the delivery of customized solutions that meet a wide range of unique application requirements.

Taking its cue from racing car pit crews, the fast-tracked development process involves the coordination of specialized internal teams with unique skillsets to ensure timely delivery of dependable prototypes that are prepared for evaluation, additional adjustments, or full-scale production.

Global Demand for Innovative Rupture Disk Designs

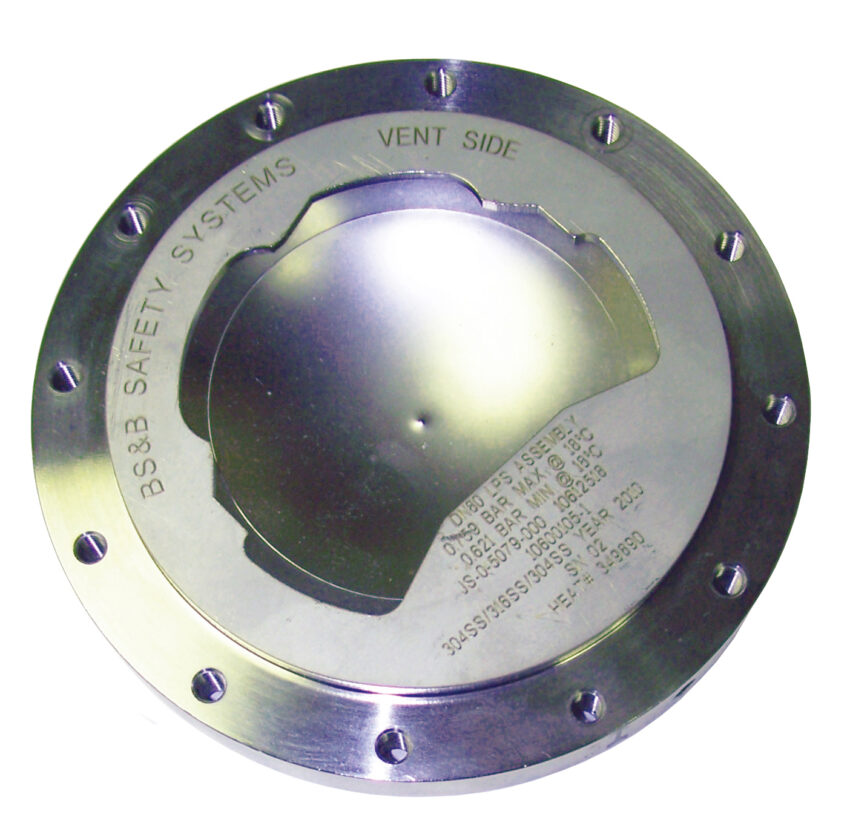

Rupture disk devices are a vital safety technology that can protect OEM equipment from potentially damaging overpressure or vacuum conditions in various processes. When customization is necessary to accommodate the OEM’s specific processes, working with an expert partner capable of expediting prototyping can dramatically improve the equipment’s reliability and longevity while reducing maintenance and overall cost of ownership.

With the global energy pivot that is occurring combined with stronger sustainability strategies, the 2020’s mark an aggressive period of innovation that impacts industries from transportation (air, rail, ship, road), to electric energy transmission, distribution & storage, with implications for the chemicals, and systems such as refrigeration and fire protection that support these technologies. The pace of creativity is faster than ever with OEM product development cycles compressed to achieve the fastest entry to market.

Consequently, OEMs increasingly require expedited delivery of rupture disk prototypes without compromising on quality or performance. Recognizing the need, rupture disk manufacturer BS&B Safety Systems developed a comprehensive support program called the Prototype Introduction Team (PIT) for OEMs that require a ‘white glove’ experience for custom rupture disk development.

The program was developed and patterned after the race car pit crew strategy, where highly trained individuals quickly and seamlessly work together—each with a specific role in the process and with a high degree of anticipation of the customers’ requirements.

The PIT™ crew’s individual responsibilities are fine-tuned for maximum efficiency, in coordination with the other members of the crew since every step can be critical to winning. Achieving rapid turnarounds requires meticulous planning, rigorous training, and exceptional teamwork. At BS&B, the PIT team involves experts assembled from sales, engineering, purchasing, manufacturing, and quality control.

The PIT program’s coordination and attention to detail has accelerated product development of custom rupture disks and accelerated OEM design decision making, according to Geof Brazier, Managing Director, BS&B Safety Systems, Custom Engineered Products Division.

For OEMs, the expedited prototype program results in rupture disks that quickly progress from concept to production level performance, price, and quality.

“Approximately two-thirds of our prototypes progress to the next development step,” explains Brazier. “Some become another prototype. Others move quickly into full production.”

For more information or assistance in selecting a solution for your application, contact BS&B Safety Systems: call (918) 622-5950; e-mail sales@bsbsystems.com; visit www.bsbsystems.com.