Photonics, the science and technology of light, relies on optical components that affect light transmission in very specialized ways. To achieve the precision required, the optical components must be precisely ground from standard forms of glass, ceramics, or other materials to exceedingly tight tolerances, in many cases with extreme levels of flatness and parallelism.

Today, advanced automated rotary surface grinders are expediting the precision optical component fabrication process, with greater control and far less damage and operator error than traditional methods.

Photonic Components

Photonics is a branch of optics that involves the generation, detection, and manipulation of light. The potential applications of photonics are virtually unlimited, including advanced science, telecommunications, information processing, photovoltaics, photonic computing, spectroscopy, holography, medicine, military technology, and robotics. Laser and amplifier systems, light-emitting diodes (LEDs), optical modulators, photodetectors, and displays are also key photonic technologies.

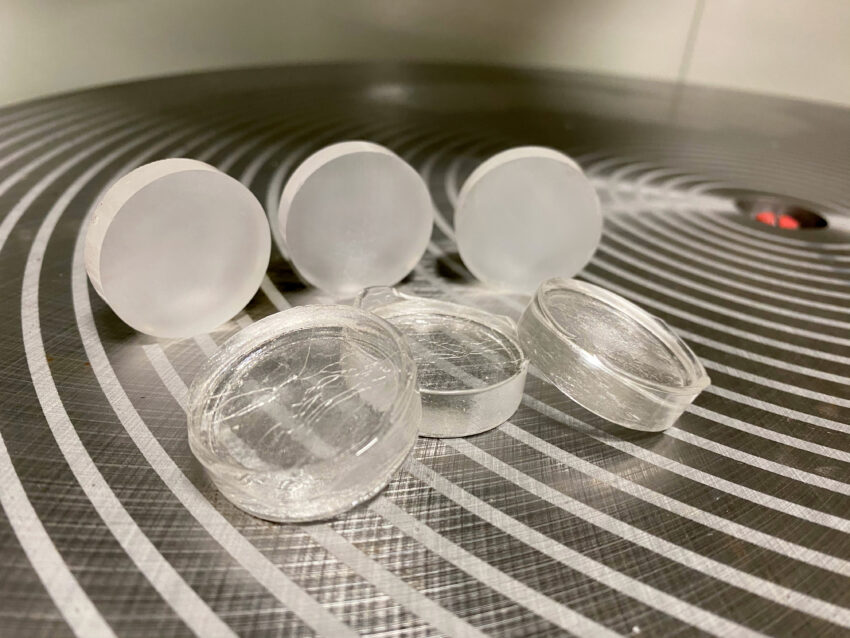

Optical components, which allow light transmission through a transparent medium like glass or ceramic, play a critical role in all photonics applications. Optical components fall into two basic groups: transmissives (lenses, filters, windows, optical flats) and reflectives (mirrors and retroreflectors). The raw materials come in a variety of shapes, sizes, and types with surfaces that are spherical, aspheric, convex, or cylindrical. They can be made from several hundred common glasses or from complex materials such as fused silica or calcium fluoride.

Flat, or plano optics, involve a range of optical components with flat, parallel surfaces with very little wedge. A plane mirror used to redirect light along an optical path, for example, is critical for applications involving images or large beam sizes because variations can alter the reflected wavefront and increase image distortion.

For many laser applications, the optical components must be flat and parallel, with a polished finish devoid of surface damage to avoid misdirecting or scattering the light.

To achieve the precise wedge or parallelism, the components must be precisely ground and finished to extremely tight dimensional tolerances.

Fortunately, advanced, automated rotary surface grinders offer advanced sensors and controls that can precisely direct the grinding process to achieve the required specifications in much less time, to ensure optimal component quality and performance. The advanced grinding equipment may also significantly reduce intermediate lapping steps and the risk of breakage of high-value optical components, further reducing costs.

Advanced Rotary Surface Grinders

According to a principal optical manufacturing engineer in the photonics industry, grinding is the first step toward creating optical glass with the required size and surface for high-quality, photonics parts.

To achieve this, photonics materials are ground down from stock material of varying size, shape, and thickness. After optical components are initially ground to remove significant amounts of material to get close to the specified size, each component is further refined. Finer grinding and polishing is performed to reach precise dimensions, tight tolerances, and a final finish – which can be challenging with older conventional grinders.

“In optics, you start with a surface grinder to get down to microns; when you finish lapping and polishing the optics, you are in the range of nanometers. At that point, the photonics parts should perform optically and interferometrically, allowing measurement using the phenomenon of light wave interference as expected,” says the photonics industry optical manufacturing engineer.

With rotary table surface grinders, the table rotates with the workpiece held firmly in place underneath a vertical spindle. With this approach, the grinding is not performed by the peripheral edge of the wheel, but rather by the entire diameter of the abrasive surface.

Traditional rotary surface grinders can lack accuracy and reliability in the hands of less experienced operators. With limited control of spindle speeds as well as manual controls, the older equipment requires sophisticated operators with a subtle touch, who can also make complex calculations. Considerable expertise and experience are required, which can be a challenge as skilled operators retire.

“We had an old rotary surface grinder that only certain operators could use. Each required special technique and would provide different results,” says the optical manufacturing engineer.

Today, surface grinders have much more advanced sensors and controls that automatically maintain extremely tight tolerances. Digital technology allows for an interface with easy-to-use touchscreen controls.

Compared to traditional grinding equipment with manual controls that require experienced machinists to be familiar with the nuances of each machine, these automated units consistently produce higher quality parts in less time. As a result, a growing number of photonic component manufacturers and machine shops are installing new grinders that can be operated by less experienced personnel while still achieving the desired results.

According to the optical manufacturing engineer, his company replaced their manually operated rotary surface grinder with an alternative from Winona, MN-based DCM Tech, a designer and builder of industrial rotary surface grinders. The IG 280 SD has a 24″ variable speed table and a 20HP variable speed grinding spindle motor. With advanced sensors and controls, the surface grinder can remove material down to one ten-thousandth of an inch of the final thickness.

“In our experience, the DCM Tech grinder is the easiest and most efficient way to achieve necessary tolerances. We can precisely control that grind, so that it cuts very well while minimizing damage,” says the optical engineer. “This makes it easy for one operator with optical knowledge to use, even if they lack experience with manual machines.”

The grinding equipment is designed with three settings that enable an easy transition from a rough to a fine grind, along with selecting a specified dwell time.

Given the performance of the system, and to allow grinding of larger components, the company recently purchased an IG 482 SD model with a 48″ rotary table, precision cross slide, and an option for part detection.

Preventing High-Value Part Damage

Another factor when grinding is that specialized optical components can cost thousands of dollars per part, so reducing or eliminating damage that can be caused during grinding can add substantially to the bottom line.

According to the optical engineer, the manually operated grinding process was inefficient, and some of the optical-grade material was ruined due to heat fractures, leading to low-yields.

Fortunately, advanced rotary grinders offer superior control with features that minimize potential damage. The automated rotary surface grinder is designed to significantly reduce or eliminate subsurface damage and edge chipping, which is a common performance gauge for operations that combine the grinding, lapping, and polishing steps in sequence. By grinding in an extremely precise, efficient manner, each subsequent step requires less time.

“Our control with the DCM Tech grinder is very good for the materials we manufacture and is much more efficient. We no longer have a yield issue,” says the optical engineer. He notes that an adjustable magnetic chuck facilitates the process by securely holding and constraining each workpiece as it is typically ground from round or rectangular stock and shaped to the necessary specifications.

He also sees value in an optional rotary surface grinder load meter, which can help to prevent excessive load related damage to the optical workpiece.

“A load meter can be particularly useful when grinding hard materials. You can set the load meter to a certain setpoint, and it will dwell at that point. If the meter senses the load has reached the setpoint, it will pause the automatic feed to avoid excessive pressure between the grinding wheel and the workpiece, and this prevents damage,” says the optical engineer.

Several additional options are also available on all DCM Tech grinders that can significantly reduce optical component damage: sensors for coolant flow, vacuum flow, and part detection.

When grinding an optical component, coolant flows to the workpiece. If the flow ceases, heat buildup can damage the component. A coolant flow sensor can prevent this issue.

“A coolant flow sensor can detect when the flow stops or diminishes and directs the machine to retract the grinding head away from the part to avoid damage,” says Mike Anderson, a technical specialist at DCM Tech.

When a machine shop uses a vacuum check to secure an optical part, any loss in vacuum between the fixture and workpiece can release the part, leading to breakage. In this case, incorporating a vacuum flow sensor can prevent the quality assurance risk. “If the flow sensor detects a drop in vacuum, the grinding head will retract from the part,” says Anderson.

In the grinding process, initiating contact with the optical component is critical. If the operator has difficulty determining contact or misjudges, it can compromise the part. Using a grinder with part detection capability can eliminate this sort of operator error by automatically finding the point of contact.

“The machine can fine-tune not only the pressure of the spindle motor but how quickly it moves the wheel down onto the part. When the machine senses the abrasive wheel has contacted the part, it then switches into grinding mode and manages itself, relieving the operator of the responsibility,” says Anderson.

When having a clean shop is desired, selecting a rotary unit with an integrated shroud to contain debris while grinding is also important. In addition to a shroud, grinders like the IG series provide an integral air mist collection system that draws particulate from the air and moves it away from the operator to enhance cleanliness and safety. To further safeguard quality, the grinders provide through-spindle and external coolant flow, as well as a self-contained recirculating filtration system with a pre-filter and in-line canister filter.

As the tolerances for photonics systems become more demanding, controlling the grinding of optical components must also become more precise. Optical component manufacturers and job shops that take advantage of advanced, automated rotary surface grinders will meet quality specifications, streamline production, and outperform rivals that rely on more traditional, manual systems.

For more information: call (800) 533-5339; email info@dcm-tech.com; visit www.dcm-tech.com; or write to DCM Tech at 4455 Theurer Blvd, Winona, MN 55987.