Today, combined cycle gas turbine (CCGT) plants play a critical role in providing power grids with additional electricity during peak periods of high demand. By harnessing the energy from both combustion and steam turbines, CCGT plants use less fuel overall and can run longer than traditional “peaker” plants to produce cheaper electricity on demand.

Depending on the condition of the region’s electrical grid, CCGT plants may be called upon to operate many hours a day, several times a week, or only a few hours per year. Regardless of their cycle frequency, however, these peaker plants must be particularly adept at quickly transitioning between their on and off status.

One of the challenges that CCGT plants face in this regard is starting their steam turbines quickly after being offline. In a combined cycle power plant, a gas turbine initially generates electricity. The waste heat from the gas turbines is then captured via a Heat Recovery Steam Generator (HRSG), which produces pressurized steam that goes to the steam turbine, enabling the power plant to generate additional electric power.

In order to be ready to provide energy as quickly as possible, CCGT plants use auxiliary boilers to reduce the cold startup time of their steam turbines, which can save as much as 30 minutes per cycle. The boilers also play a critical role in maintaining the readiness of condensers whose function is to turn the steam recovered from the turbines back to water.

“You have to generate the steam to start the turbine turning and that is one of the major uses of auxiliary boilers,” said Robert Presser, Vice President of Acme Engineering, a manufacturer of industrial and commercial boilers with operations in the U.S., Canada, and Europe. “When you need an auxiliary boiler to start the turbine, you need a lot of power and you need it fast.”

Managing an ‘on and off again’ relationship

In one example, Acme Engineering was asked to provide a 3-megawatt conventional electric boiler system for Goreway Power Station in Brampton, Ontario. The 875 MW natural gas-fueled combined cycle plant provides electricity to Ontario’s power grid on a 24/7 basis while primarily operating as a peaking power or “peaker” plant during intermediate and peak demand periods.

Unlike traditional peaker plants that might be called upon to supply energy periodically with long and predictable periods offline, Goreway needs to manage a daily online/offline rhythm.

“We typically cycle on and off multiple times a day,” said Chad Donnelly, Shift Engineer at Goreway. “We need to support morning peak, then we’ll shut down through the mid-day peak before restarting for the evening peak and then typically shut down for overnight.”

When the main HRSG boiler is offline, superheated steam and pressure is lost so Goreway uses their auxiliary boiler to supply steam to maintain the condenser vacuum. This required their engineering team to develop an operating cadence to maximize the plant’s readiness to provide energy efficiently.

“We use an auxiliary boiler to ramp up an hour before shutdown and supply the shaft seal with steam while the units are down so the plant is ready for a quick start in the morning,” said Donnelly. “Using an auxiliary boiler increases the flexibility of the facility because we only have to run this small auxiliary boiler to maintain a vacuum in the condenser.”

Going electric

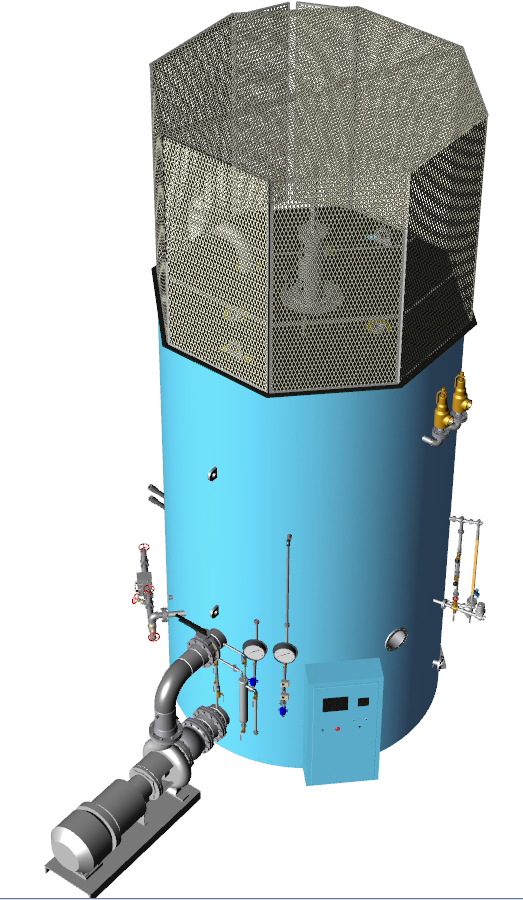

After considering their options, the engineering team selected a 3-megawatt electrode-based electrical boiler from Acme Engineering as their auxiliary boiler. In addition, Acme Engineering integrated the feedwater pumps that go to the boiler, a steam separator, and an electric steam superheater and delivered it on a skid as a complete system.

Today, the flexibility, precision, and responsiveness of modern electrode boilers allow cost-effective “on demand” superheated steam almost immediately.

“A gas-fired boiler cannot go from zero to 100% capacity in less than two minutes – but an electrode boiler can,” says Acme Engineering’s Presser. He points out that modern electrode boilers are designed so temperature, pressure, and output can quickly rise or fall as needed with no “flywheel effect.”

Electrode boilers have existed in various forms for many decades. However, recent design improvements have closed the output gap while surpassing conventional units not only in terms of efficiency and simplicity but also responsiveness and safety.

Modern electrode boilers utilize the conductive and resistive properties of water to carry electric current and generate steam. In a jet boiler, water jets flow from a central column to electrodes of each phase, using chemicals in the water to create resistance and generate heat and steam as the water passes from ground to phase. More steam is produced as the water flows from the electrode to the counter electrode placed below the electrode box, before the water returns to the reservoir at the bottom of the vessel.

“The more current [amps] that flows, the more heat [BTUs] is generated and the more steam produced. Nearly 100% of the electrical energy is converted into heat with no exhaust stack or heat transfer losses,” says Presser.

Other advantages of electric boilers include a fast start-shutdown cycle speed, a high degree of control and accuracy in temperature, energy efficiency, convenient operation and maintenance, and low carbon emissions.

“It’s an environmental win because instead of burning more fossil fuel, Goreway is running on off-peak electricity to supply our auxiliary boiler,” explains Donnelly. “Off-peak electricity is generally pretty green too as it is provided by the nuclear stack or excess wind generation when we are offline.”

Goreway runs their auxiliary boiler in a warm standby mode, maintaining a slight 200 kPa pressure inside the drum for even quicker startup and chemistry stability.

“An hour before shutdown we essentially just hit “boiler start” and it changes the set point to 700 [kPa] and it comes online,” said Donnelly. “Once the steam flow is established, the superheater comes online to dry the saturated steam, increase its thermal energy, and reduce the risk of condensation as compared to unheated saturated steam.”

Donnelly acknowledges that on a large scale, sustained basis, it may be less expensive to operate a gas-powered auxiliary boiler system; however, he points out that you need to already have a gas supply, gas contracts, environmental contracts, and operators that are experienced in using natural gas.

In Goreway’s situation, since the plant was already under construction when they were selecting an auxiliary boiler system, they did not want to delay construction or incur the added costs by bringing in natural gas lines for an auxiliary boiler and new environmental permit, so they chose an electric solution.

Maximizing efficiencies through collocation

One of the benefits of using an electric auxiliary boiler is the versatility in where to locate them. Since operationalizing their electrode system, Donnelly has new insights on what would make an ideal configuration.

Donnelly recommends locating a separately-fired electric superheater close to where the steam is needed to minimize temperature loss. “With a conventional boiler, you just can’t do that because it’s kind of an all-in-one package, ” he added.

In Goreway’s case, Donnelly judges their ideal location as their sealed-steam skid because the saturated steam can go from the HRSGs to the electric superheater until the pressure decays, then the electric boiler can supply steam until the next startup.

Electric boiler systems offer CCGT plants a highly configurable solution for the operational readiness of their steam turbines. From accelerated starts to robust support for maintaining condenser vacuums, they are a targeted ‘clean and green’ component that can be easily configured to each plant’s unique needs.

For more info, contact Robert Presser at Acme Engineering via e-mail: rpresser@acmeprod.com; phone: (888) 880-5323 or (514) 342-5656; or web: https://www.acmeprod.com/jet-type-steam-boiler.