Automated scraper strainers paired with macerators eliminate high volumes of large, suspended solids from slurries for “set it and forget it” approach.

In the poultry processing industry, industrial strainers are used to separate high volumes of skin, hair, feathers, grit, fats, and other particulate organic material or suspended solids from liquids and slurries before further filtration, treatment, and discharge of wastewater from the plant. This is necessary to comply with local, state, and federal environmental regulations.

However, conventional strainer methods can prove to be unreliable and lead to extensive maintenance, particularly in cases where the debris or solids are of substantial size and there is a significant amount of suspended solids present.

The combination of a macerator and automated scraper strainer can effectively remove tough debris and particles while handling high solids loading without clogging.

Overcoming traditional limitations, this technology eliminates the need for time-consuming and messy cleaning processes associated with conventional duplex basket strainers. This solution has been successfully applied in various industries including wastewater treatment, power generation, food processing, and chemical manufacturing.

“The combination of established complimentary technologies – a macerator and an automated scraper strainer – can essentially ‘knock out’ even the toughest problems related to large solids and high solids loading in an automated way,” says Robert Presser, Vice President of Acme Engineering Prod., Inc., a North American manufacturer of industrial self-cleaning strainers. The company is an ISO 9001:2015 certified manufacturer of environmental controls and systems with integrated mechanical, electrical, and electronic capabilities.

In this configuration, a macerator would be installed upstream to reduce large solids down to a manageable size. The capabilities of the automated strainer are crucial to the process as well.

“Although the macerator cuts up the biggest solids, the strainer must still be able to separate both relatively large pieces and tiny particles while handling high solids loading without becoming obstructed,” explains Presser.

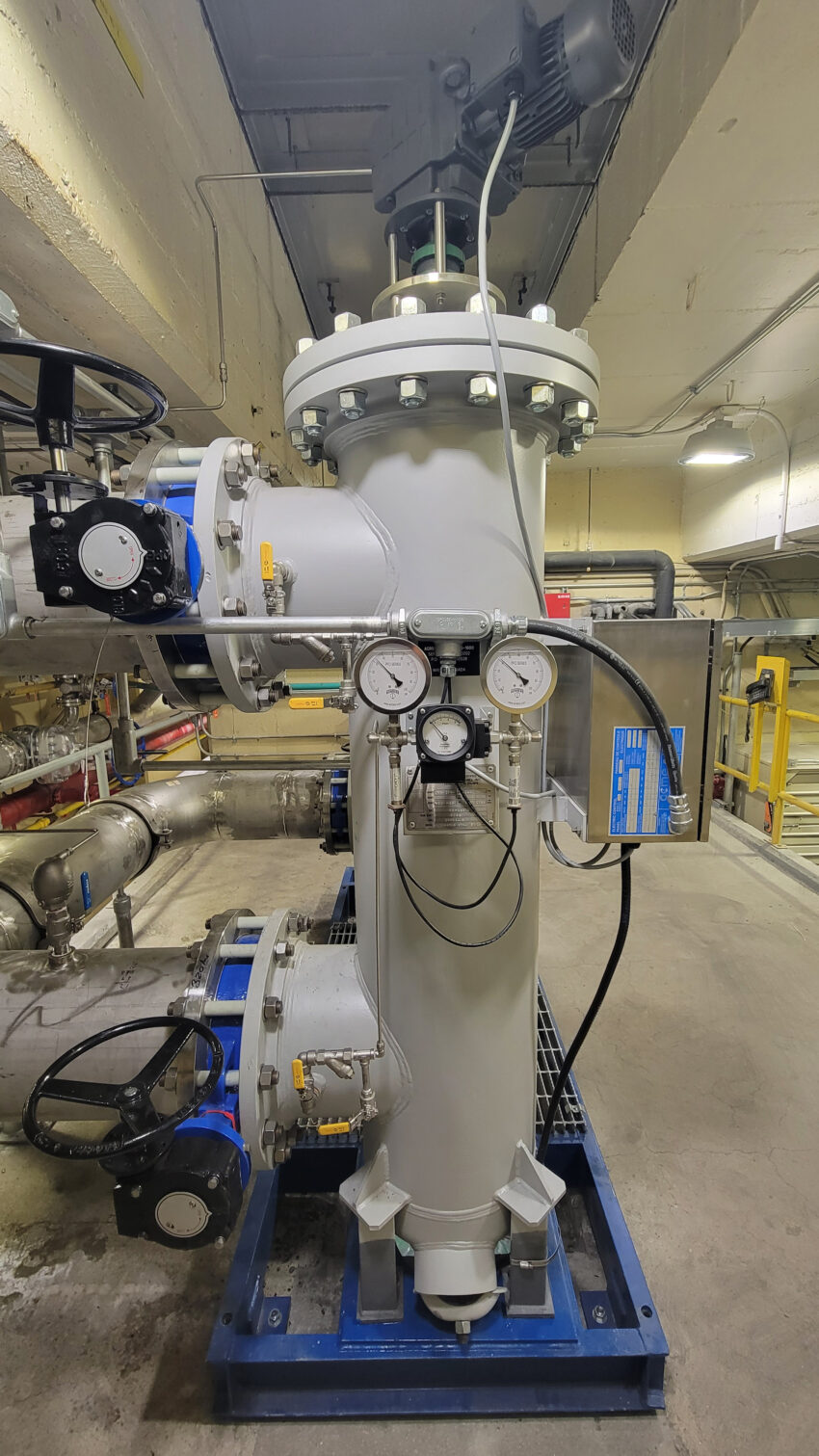

In the case of Acme, the OEM’s automated scraper strainer is designed to continually remove both very large and very small suspended solids from liquids and slurries. Cleaning is accomplished by a spring-loaded blade and brush system, managed by a fully automatic control system.

According to Presser, Acme has already worked with plant operators and managers to implement a wide range of specialized straining systems for difficult applications with exceptionally large solids or very high solids loading.

For one poultry processing application, Acme Engineering designed an automated strainer for a producer to remove unwanted waste solids from a thick slurry. Although a macerator was not used in conjunction with the strainer for this application, it could have significantly improved the efficiency of the process with increased automation and reduced labor.

In the industry, poultry processors depend on the filtration of liquids or slurries to meet quality and regulatory standards. When the removal of large solids or managing excessive solids loading exceeds the feasibility of manual basket strainer cleaning, integrating a combination of highly effective technologies may be the best decision.

For more info, visit Acme Engineering Prod. Inc. at acmeprod.com; or phone Robert Presser, Vice President at: 518-236-5659.