A new feature of the modern high-powered laser is the need to transmit various wavelengths through fiber optics. Fiber optics have emerged as the primary method for transmitting laser light due to its ease of setup and disconnection. Moreover, it safeguards end users from light exposure or eye contact, as the light is conveyed through an enclosed conduit.

“I would estimate 60 to 70% of our customers today are asking for the light to be delivered through fiber, and it is quickly becoming a requirement for university researchers and OEMs that integrate high powered lasers into a larger system,” says Dr. Mark Little, Technical and Scientific Marketing Consultant for Carlsbad, CA-based OPOTEK LLC, a global manufacturer of tunable lasers that can deliver wavelengths from deep UV to mid-infrared.

However, it is critical to select the right type of fiber material to transmit the light without damage, as well as have other design features that promote safety. With high powered lasers, this often means involving a custom fiber optic supplier that can recommend a specific solution optimized for the wavelength and intensity of the laser that will be utilized.

For optimal results, some of the custom fiber optic choices that should be considered are:

• Flexible pulse-based lasers Optical Parametric Oscillators (OPO) lasers that can be “tuned” to a wide spectrum of specific wavelengths. OPOs are utilized in sophisticated test and measurement applications such as mass spectrometry, photoacoustic imaging, and spectroscopy.

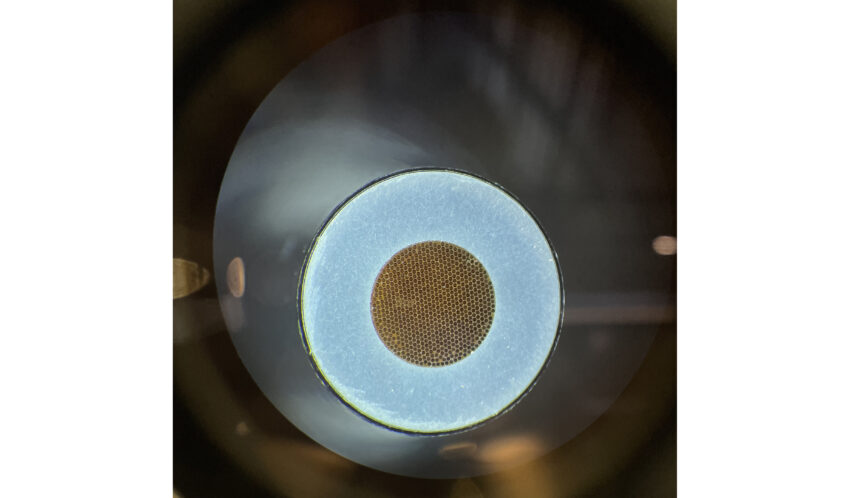

• Single strand, large core optical fibers designed to handle higher power levels. These optical fibers can offer better performance in certain applications, even when the laser source is low energy.

• Fiber bundles comprised of many thin, flexible strands of optical fiber made of glass or plastic. The fiber bundles are capable of transmitting light signals over long distances with minimal loss. By combining multiple fibers, the bundles can carry more data or power than a single fiber. Multiple fibers can also prevent damage and manage heat dissipation.

• Applying special chemistry treatments and utilizing unique optical materials to prevent light absorption and UV damage in Deep UV wavelengths. Solarization, or “photobleaching” of the fiber can occur due to prolonged exposure to UV or other forms of radiation. Solarization causes a gradual increase in the absorption of light, leading to a decrease in fiber performance.

Today’s high-powered lasers demand efficient and safe transmission methods, and fiber optics have emerged as a leading solution. Still, the key to success lies in selecting the right fiber material and custom solutions tailored to the unique requirements of each application to avoid damage and optimize performance. By leveraging advanced fiber technologies, OEMs can achieve precise alignment, enhanced flexibility, and reliable performance, making high-powered lasers more accessible and effective for a wide range of applications.

For more information, call 760-929-0770 or visit www.opotek.com.